The main types of hydraulic pumps include gear pumps, vane pumps, piston pumps, and screw pumps.

Classification of Hydraulic Pumps

Hydraulic pumps are an integral component of any hydraulic system. They are responsible for converting mechanical energy into hydraulic energy, resulting in fluid motion. The different types of hydraulic pumps are primarily classified based on their design and operation mechanism.

Overview of Different Types

There are four main types of hydraulic pumps: Gear Pumps, Vane Pumps, Piston Pumps, and Screw Pumps. Each type of pump has a unique mechanism of operation and is suited to specific applications.

- Gear Pumps are the simplest type of hydraulic pump. They use the meshing of gears to pump fluid by displacement. These are robust pumps for moderate pressures.

- Vane Pumps use a rotating slotted rotor to move fluid against a hard edge. They are often used in automotive power-steering systems.

- Piston Pumps are a type of hydraulic pump that uses a piston moving back and forth in a cylindrical chamber to pump fluid. These pumps can handle very high pressures and are often used in industrial settings.

- Screw Pumps have a mechanism that uses two or more meshed screws to pressurize fluids. They are commonly used in high-flow, low-pressure applications due to their smooth, pulseless flow characteristics.

Each of these pump types comes with its own set of advantages and drawbacks. The right type for a given application depends on a variety of factors, including pressure requirements, efficiency needs, and the nature of the hydraulic system.

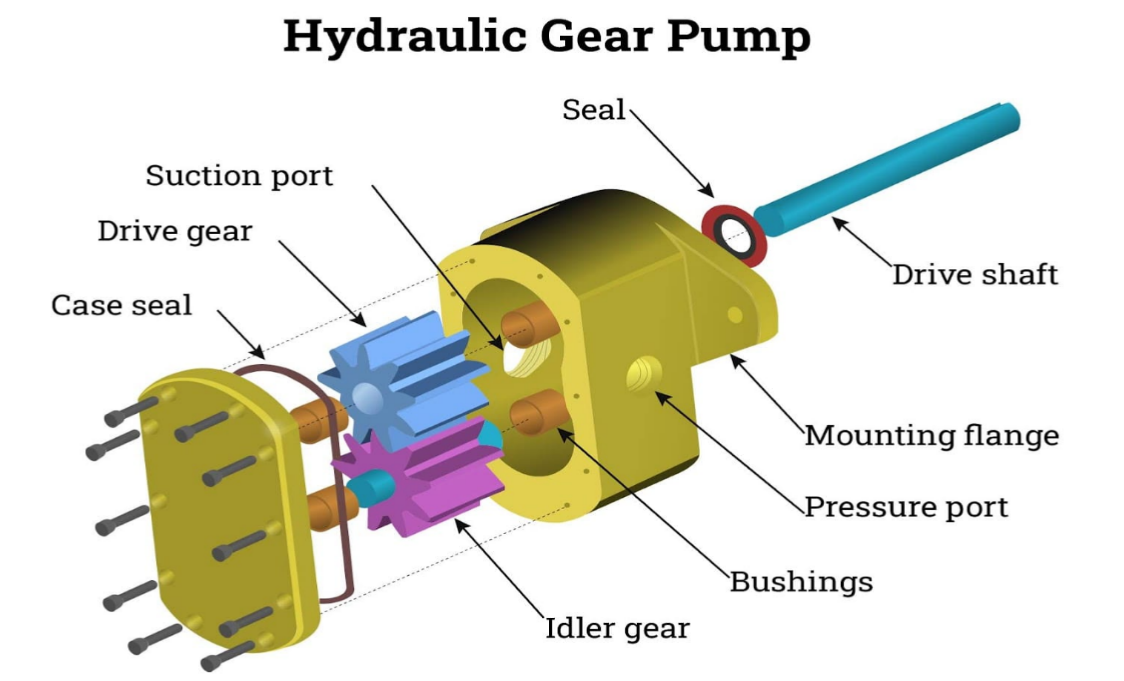

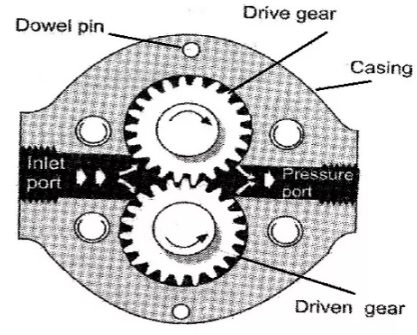

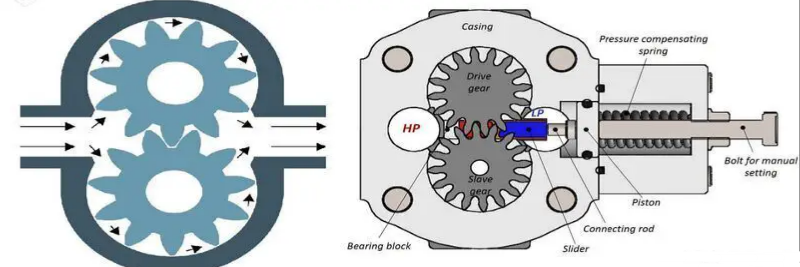

Gear Pumps

Gear Pumps are among the most common types of hydraulic pumps due to their simplicity, efficiency, and compactness. They operate using the principle of displacement and utilize a set of gears to move fluid.

Description and Operation

Gear Pumps operate using two meshed gears which revolve in a closely fitted casing. When the gears rotate, fluid gets trapped in the pockets between the gear teeth and the casing, causing it to move from the inlet to the outlet side of the pump. The operation of these pumps is highly reliable and straightforward, leading to their wide adoption across various industries.

Common Applications

Due to their high durability and effectiveness, gear pumps are used in numerous applications. Some of the most common applications include hydraulic power units, power steering systems, and material handling equipment. They are also widely used in construction machinery, farming equipment, and lubrication systems for machinery and vehicles.

Advantages and Disadvantages

One of the main advantages of gear pumps is their simplicity of design, which results in a reliable and compact pump with fewer moving parts. This leads to easier maintenance and higher mechanical efficiency.

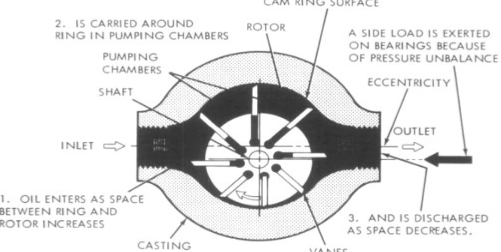

Vane Pumps

Vane Pumps are a type of hydraulic pump that are distinguished by their unique design, which employs vanes to move the fluid. They offer medium to high flow rates and can operate under a wide range of pressures.

Description and Operation

A Vane Pump operates by using a rotor with radially positioned slots in which the vanes reside. As the rotor spins within the cam ring, centrifugal force extends the vanes from their slots, creating individual cells between the vanes. Fluid is drawn in as the volume of these cells increases and is expelled as the volume decreases. This design enables smooth, pulse-free output flow.

Common Applications

Vane pumps are known for their quiet operation and are often found in automotive, industrial, and hydraulic applications. These include power steering systems, automatic transmissions, and air conditioning units. In industrial contexts, they’re used in machine tools, molding machines, mining machinery, and material handling equipment.

Advantages and Disadvantages

Vane pumps are appreciated for their quiet operation, high efficiency, and ability to handle viscous fluids. They can produce high flow rates and tolerate contamination better than other pump types. However, they’re less robust than gear or piston pumps and can experience reduced performance or failure if used in high-pressure systems. The vanes are also subject to wear, which can lead to decreased efficiency over time.

Piston Pumps

Piston Pumps are versatile hydraulic pumps that are known for their high pressure capability, efficiency, and robustness, making them suitable for a variety of heavy-duty applications.

Description and Operation

Piston Pumps operate by using pistons to create pressure and move fluid. A common design involves a number of pistons in a circular array within a cylinder block. When the pistons reciprocate, they draw in fluid on the inlet stroke and expel it on the outlet stroke. The piston’s motion varies between pump designs, with some using a swashplate mechanism and others employing an axial or radial design.

Common Applications

Piston pumps are utilized in many high-pressure applications. They are common in industries like construction, where they power hydraulic systems in machinery such as excavators and cranes. They’re also found in applications like marine equipment, oil & gas operations, mining equipment, and in high-pressure water cleaning and desalination processes.

Advantages and Disadvantages

One of the key advantages of piston pumps is their ability to generate high pressures and maintain high efficiency. They are also capable of variable flow rates and can be very robust, which makes them suitable for demanding applications.

Screw Pumps

Screw Pumps, also known as helical rotor pumps, are a type of rotary positive displacement pump. They are notable for their ability to deliver a smooth, pulseless flow and operate quietly, making them suitable for certain specific applications.

Description and Operation

Screw Pumps operate using two or three intermeshed screws that rotate to move fluid along the axis of the pump. As the screws rotate, they create cavities that trap fluid, transporting it from the inlet side to the outlet side of the pump. Due to their design, screw pumps can handle a wide range of fluid viscosities and temperatures.

Common Applications

Screw pumps are commonly used in industries where low noise levels, high efficiency, and a smooth, steady flow are required. This includes applications in oil and gas production, food processing, chemical industries, and marine applications like fuel transfer systems. They are also used for handling lubricating oils in mechanical systems.

Advantages and Disadvantages

Screw pumps offer numerous advantages, including low noise levels, high efficiency, and the ability to handle a wide range of fluid viscosities and temperatures. They also provide a smooth, pulseless flow, which is beneficial in many applications.

Comparison of Different Pump Types

When choosing a hydraulic pump, it’s crucial to consider the specific needs of the application. Each pump type has unique characteristics that may make it more suitable for certain uses. Here, we compare the four main types of hydraulic pumps based on several important parameters.

Performance and Efficiency

Piston Pumps tend to offer the highest operational pressures and maintain high efficiency even at these high pressures. Gear Pumps and Vane Pumps are known for their reliability and can deliver moderate pressures efficiently. Screw Pumps, while offering lower pressures, provide a smooth, constant flow and are especially efficient when handling high-viscosity fluids.

Size and Cost

Generally, gear and vane pumps are smaller and less expensive than piston and screw pumps. However, the cost can also depend on the specific design, material, and manufacturer of the pump. For high-pressure systems, the initial cost of piston pumps may be justified by their robustness and long-term performance.

Maintenance Requirements

Simplicity is a virtue when it comes to maintenance. Gear pumps, with their simple construction and fewer moving parts, typically require less maintenance. Piston pumps, while offering high performance, can be more complex and may require more frequent maintenance, especially if the hydraulic fluid is not kept clean. Screw pumps, due to their precision-made intermeshing screws, can also have higher maintenance requirements.

Suitability for Different Applications

The suitability of a pump type largely depends on the application requirements. For high-pressure, heavy-duty applications, piston pumps are usually preferred. Gear pumps find use in a variety of applications due to their reliability and compactness. Vane pumps are often chosen for systems requiring low noise, such as automotive applications. Lastly, screw pumps are ideal for applications requiring a smooth, pulseless flow, especially when handling viscous fluids.

Selecting the Right Hydraulic Pump

Choosing the appropriate hydraulic pump is crucial to the efficiency and longevity of your hydraulic system. It involves understanding your system requirements and using specific selection criteria to make an informed choice.

Understanding System Requirements

Before selecting a pump, it’s essential to understand your hydraulic system’s requirements. This includes factors such as:

- The operating pressure and flow rate

- The type and viscosity of the fluid being pumped

- The system’s duty cycle

- The operating environment, including ambient temperature and potential exposure to dirt or moisture

Selection Criteria

Once you’ve understood your system requirements, you can consider specific criteria to select the appropriate pump. These include:

- Type of Pump: As we have discussed in the previous sections, different pump types (gear, vane, piston, screw) have different strengths and weaknesses. Choose the one that best suits your needs.

- Performance: The pump should be able to deliver the necessary flow at the required pressure.

- Efficiency: Higher efficiency pumps will use less power to do the same amount of work.

- Reliability and Durability: The pump should be robust enough to withstand the operating conditions for a prolonged period.

- Cost: Consider both the initial purchase price and the ongoing maintenance costs.

References:

- Hydraulic Pump Wikipedia Page

- Gear Pump Wikipedia Page

- Vane Pump Wikipedia Page

- Piston Pump Wikipedia Page

- Screw Pump Wikipedia Page